Safety in the Fablab

When in the Fab Lab, proper safety precautions have to be followed to ensure the safety of yourself and the others around you.

Attire

The first thing that has to be watched out for is your attire.The video below will go through what is the proper attire for the workshop

Video on workshop Safety.Before using the machine

Before using the machine, remember to read the plycards on the machine and remember to check that emergency stop buttons and brakes work. If you are unsure of how to use the machine, there is no shame in asking the people around you for guidance.

Placards on the machine

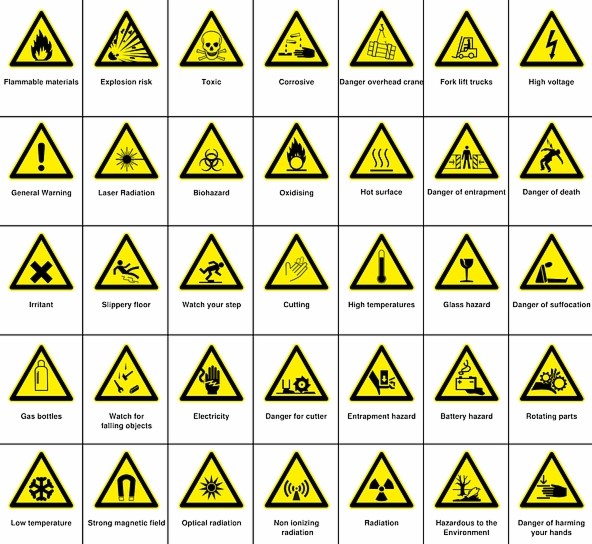

Each machine has placards which indicate the danger levels of the machine, the potential hazards that come with using the machine and what protective epuipment has to be worn before operating the machine.The placard also contains things that have to be remembered while using the machines.

Hazards associated with machinery and workplace

There are three primary areas where hazards can occur

- The machine's perimetre

- The "drive train"

- Points of operation

Machine perimetres

The machine's perimetre refers to the area around the machine, where falling objects, flying debris or other hazards can occur.

The "drive train"

The drive train refers to all moving parts that run the machine.

Points of operation

The points of operation refers to the location where a machine's mechanical or electrical energy is used to cut, bend or otherwise process materials.

Machine Hazard Identification

Typically, 2 areas on the machinery are dangerous , and can be a hazard for anyone near the machine.The two areas are:

- Parts which move or transmit power

- Belts, Chains and Pulleys

- Gear Trains and Sprocket gears

- Shaft and Spindles

- Slides and Flywheels

- Parts that do work

- Blades

- Cutters and Tool Bits

- Saws

- Drills and Chucks

Mechanical Hazards

Types of hazards due to machinery motions:

- Entanglement Hazards

- Cutting Hazards

- Impact Hazards

- Shearing Hazards

- Crushing Hazards

- Draw-in Hazards

- Friction and Abrasion Hazards

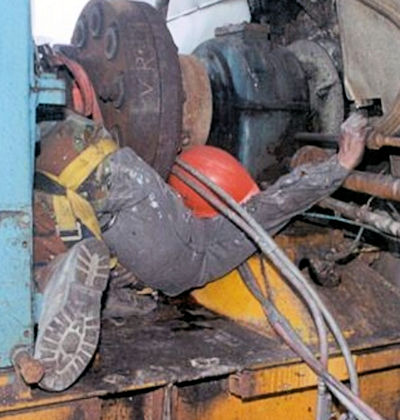

Entanglement Hazards

Entaglement arise when loose clothing, hair or loose items get caught in the moving parts of the machine.

Entanglement Hazard video

Entanglement Hazard video

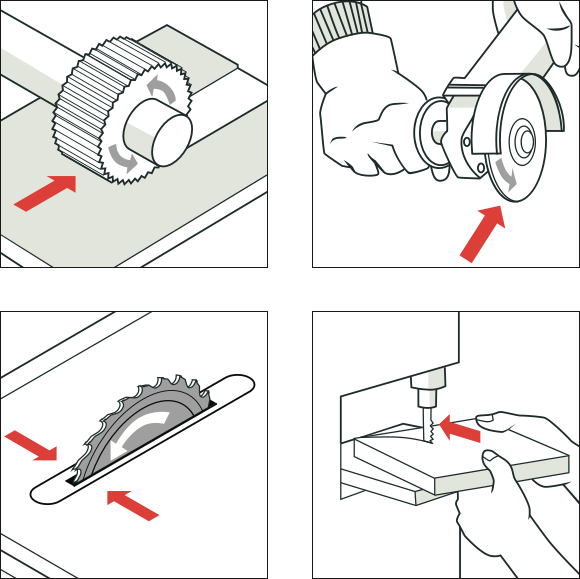

Cutting Hazards

Cutting hazards are present in machines that cut wood, metal or any other materials at the point of operation.Machines with moving cutting elements can cause severe injury(eg. deep cuts, amputations> due to its own momentum when it comes in contact with the user's body.

Cutting Hazard video

Cutting Hazard video

Draw-in Hazards

Draw-in hazards can occur when a body part is drawn-in by in-running nip points formed by two counter-rotating parts or between rotatinng and tangentially moving surfaces.

Non-Mechanical Hazards

Non-Mechanical hazards include:

- Fall from Heights Hazard

- Noise Hazards

- Electrical Hazards

- Heat-Related Hazards

- Chemical Hazards

- Fatigue

- Ergonomic Risk Factors